A family-owned business

with the extraordinary service range

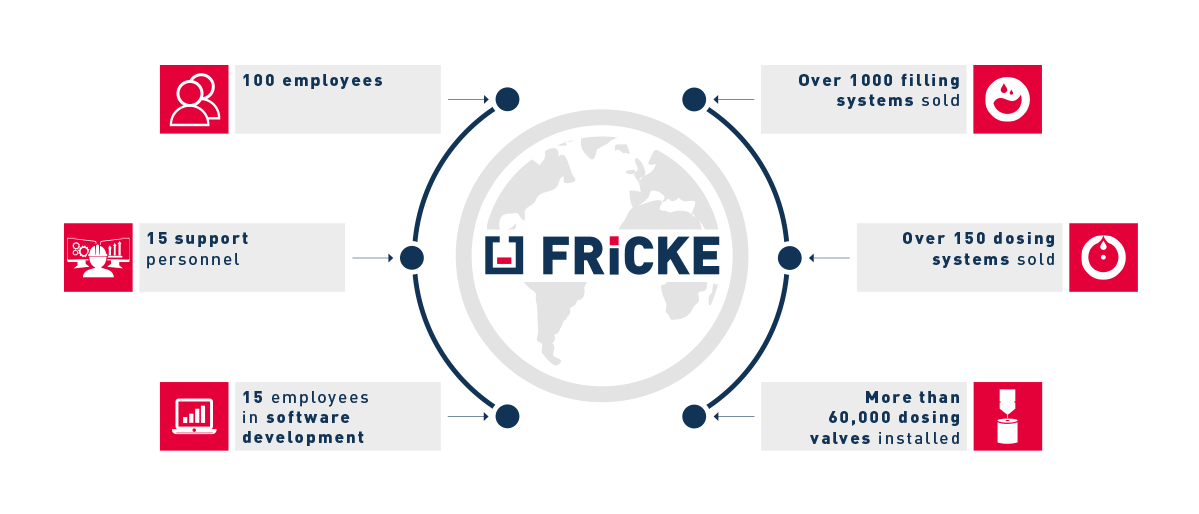

FRICKE Dosing + Filling Systems from Minden operates globally and serves customers from all over the world with high-quality plant technology and future-oriented software.

With focus on the product-specific requirements of liquid substances, FRICKE is the preferred partner of the perfume and aroma industry as well as the chemical industry.

At FRICKE, a broad range of engineering know-how, more than 150 years of experience and the traditional values of a family-run company combine to create a distinctive customer culture: Anyone who wants to meet the highest standards needs to do an extraordinary job.

A challenge that requires commitment at all levels and from every employee. As a modern family business, FRICKE therefore relies on clear, flat structures and open communication, which promotes creative ideas as well as responsible action.

FRICKE stands for specialization, performance diversity and focused management. Choose a production solution from FRICKE and see for yourself:

- guaranteed quality products "Made in Germany"

- tried and tested long-term employees

- high consulting and planning competence

- extensive product range

Establishment

- The great-great-grandfather of today's managing director founds a locksmith's shop in Rehme (Westphalia)

- Decimal scales for use in farming, trade and industry

Job enlargement

Scales for bulk goods

Sack filling scales

Werner Fricke presents the first sack filling scales for solid combustibles at the trade fair in Hanover

Paint and lacquer industry

- Development of the first filling system for the paint and lacquer industry

- Filling systems for the paint and lacquer industry

Dosing systems

- Involvement in the construction of the most extensive dosing plant of the time

- Dosing plants for the perfume and aroma industry

Dosing software

Development of the comany's own dosing software

First trade fair presentation

First trade fair presentation at the Achema

Relocation

Relocation to the new company building in Minden, Meißen

BMS

Development of the BMS (PPS programm for the perfume and aroma industry)

Management

- Werner Fricke hands over the management of the company to Stephan Fricke

- Establishment of the Fricke Branch in the USA

Annex

Addition of a 622 m2 large production hall

Warehouse / Production hall

Construction of an 800 m2 large warehouse / production hall.

Extension

Extension of the office space by 400 m2

Improved logistics

The addition of two vertical bearings creates optimal conditions for the growing needs of production and support.

Expansion

Thanks to the acquisition of an adjacent industrial area, the service and sports department gains new rooms.

20 years in Meißen

Small anniversary, great perspective: Today, customers are all over the world rely on the technology of FRICKE.

Storage Area Expanded

Thanks to the new hall construction, our storage capacity has been expanded by a further 1000 m2.

Matsubo Corporation

33 Mori Bldg. (4F)

3-8-21,

Toranomon, Minato-ku,

Tokyo105-0001, Japan

Fon: + 81 (0)3 5472-1736

Fax: + 08 (0)3 5472-1730

suzuki.jumpei(at)kobelco-matsubo.com

www.matsubo.co.jp

F.I.S.T. Science & Technology LTD

Room 2407-2409,

Construction Building,

East Dongfeng Road 36,

Kunming City, Yunnan Province, China

Fon: (+86)871-63190886

(+86)871-63191225

Fax: (+86)871-63191505

admin(at)fisttech.com

www.fisttech.com

GOBAC d.o.o.

generalno zastupstvo

Brescenskoga 9 / V

HR 1000 Zagreb

Fon: +3 85 (1) 46 19 501

Fax: +3 85 (1) 45 54 275

gobac(at)zg.htnet.hr