Software: BMS

The planning software for your production processes

The Batch Management System, briefly termed BMS, is a Windows database tool especially devised for the production of perfumes and aromas. Having been in use worldwide since 1997 and continuously further developed, the BMS is particularly operator friendly. Based on the familiar Windows standards, detailed documentation and integrated help functions facilitate simple handling.

User administration

User administration

Capture user profiles with various access rights

Order splitting

Order splitting

Split production orders to multiple systems

Recombine

Recombine

Database technical merging of orders

Administration

Administration

BMS manages orders, stocks and containers

Interfaces

Interfaces

Flexible import and export functions to your database

Batch tracing

Batch tracing

By means of barcode-controlled dosing, we ensure batch tracing up to the smallest addition.

Free dosage rules

Free dosage rules

The dosing rules are freely parameterizable

Languages

Languages

BMS offers the language options German, English, French, Spanish and Dutch

Modular design

Optionally adaptable to your requirements

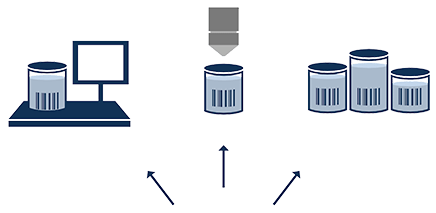

With its modular design FRICKE BMS forms the interface between your own host computer and the automatic dosing systems, including manual addition.

ONE SOLUTION, MANY ADVANTAGES

FRICKE BMS is the perfect management software for your batch processes

GET STARTED NOW WITH BIS.

We would be pleased to discuss with you which BMS concept and modules are best suited to you.

FAQ

If you cannot find an answer to your question about BMS from FRICKE, we would be glad to answer it personally.

How can I access the database entries in the BMS?

Do I need an ERP system as a prerequisite for BMS?

With which ERP system does BMS work?

Can I create various user groups with different rights under the BMS?

Can I manage the material warehouse in BMS?

Can the BMS manage mixing containers?

Can I use the BMS on multiple computers / machines?

Are upgrades also included in my license?

Are upgrades also included in my license?

Yes, the upgrades for troubleshooting are included during the warranty period. After the warranty expires, upgrades for troubleshooting are covered by a maintenance and service contract which is subject to a charge. Upgrades to increase performance, as well as operating system or server changes, are discounted in comparison to a new BMS system. The installation costs are invoiced at cost.

![[Translate to Englisch:] BMS Monitor mit Labledrucker](/fileadmin/user_upload/bms-keyvisual-monitor-labledrucker.png)