ANY QUESTIONS?

All plants can be adapted to yourspecific requirements.

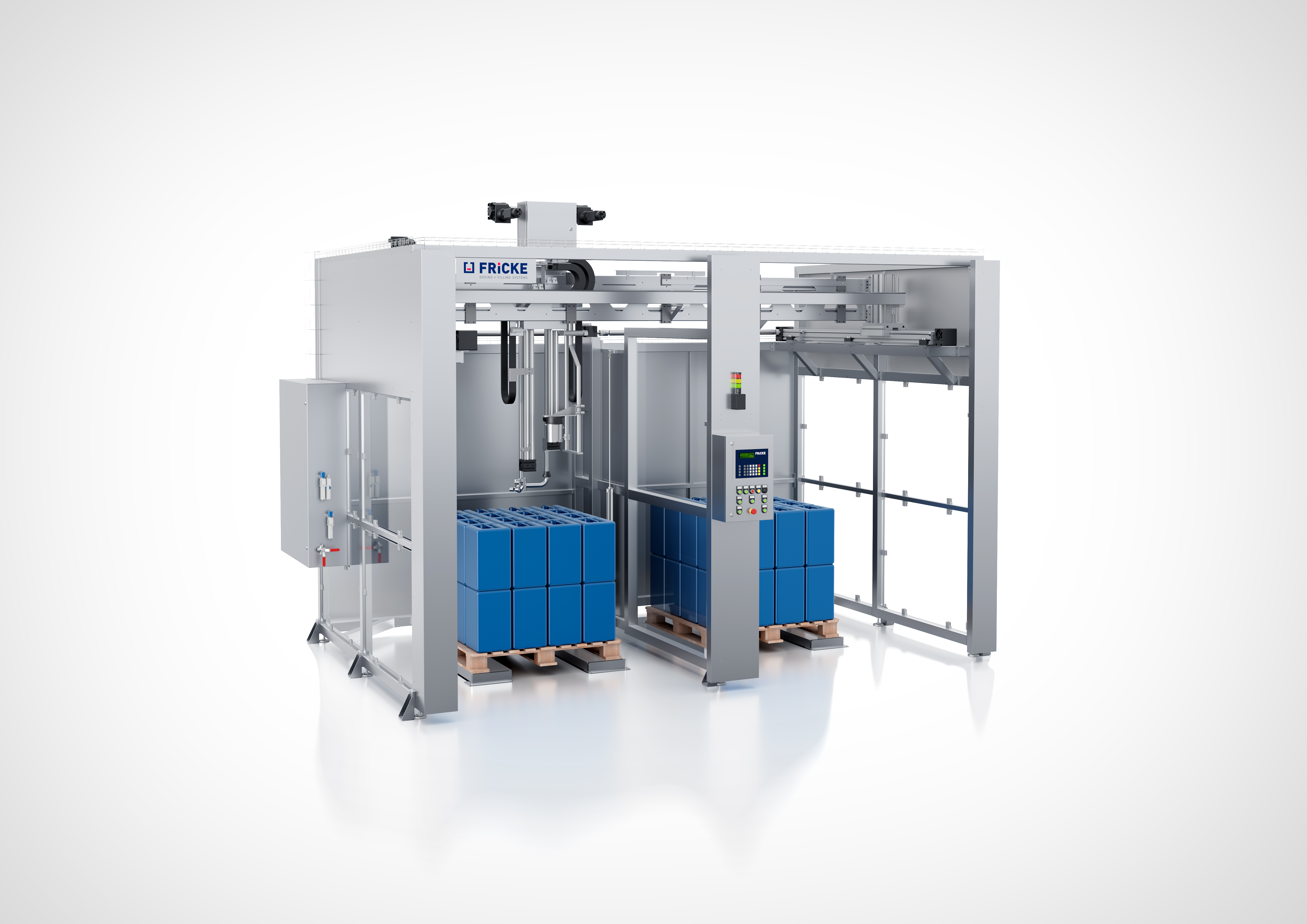

With the FFS 20 (coordinate filling system with "teach in") or AFS 20 (coordinate filling system with camera), FRICKE presents another innovation that sets new standards.

Designed in a robust stainless steel construction and prepared for automatic bunghole detection, this system guarantees not only accurate, calibratable filling but above all: high efficiency. Because, whilst in the case of conventional machines the container is guided to the valve, the FFS 20 (coordinate filling system PK) does exactly the opposite! This means an immense time saving, especially for pallet filling of different containers.

The relatively light valves move at an enormous speed and are easy and fast to clean due to only three components which have direct contact with the material. Thus, changeover times are reduced to a minimum.

Further advantages: The filling is almost foam-free and is also suitable for critical materials. The integrated level tracking guarantees a corresponding lifting of the valve as the filling level increases. And regardless of container size and quantity, all processes can be retained and made available on demand.

What sounds like intensive handling and complicated can be easily implemented by one person in only three steps:

- Position the pallet (below the system)

- Documenting the container positions via camera

- Start the filling process

If you require more information, please call us.